In today's fast-paced world, printing plays a crucial role in various industries, enabling the dissemination of information and the creation of tangible products. Understanding the different types of printing is essential for professionals seeking to optimize their printing processes and achieve the best results. In this blog post, we will delve into the four main types of printing, exploring their unique characteristics, applications, and advancements. So, let's embark on this informative journey and unravel the world of printing!

- Offset Printing:

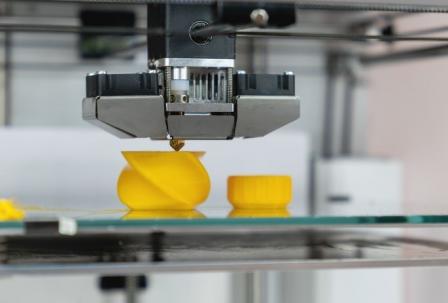

Offset printing, also known as lithography, is a widely used technique that involves transferring ink from a plate to a rubber blanket and then onto the printing surface. This method is ideal for high-volume projects, such as newspapers, magazines, and brochures. Its key advantages include excellent image quality, cost-effectiveness for large quantities, and compatibility with various paper types. Recent advancements in offset printing include computer-to-plate technology, enhancing precision and reducing setup time. - Digital Printing:

Digital printing revolutionized the industry by enabling quick and cost-effective printing with minimal setup requirements. This method involves transferring digital files directly onto the printing surface, eliminating the need for plates. Digital printing is highly versatile, allowing customization and personalization, making it suitable for small print runs, variable data printing, and on-demand production. With advancements in inkjet and laser technologies, digital printing now offers enhanced color accuracy, faster speeds, and expanded substrate compatibility. - Flexographic Printing:

Flexographic printing, commonly used for packaging materials, labels, and newspapers, utilizes flexible relief plates and fast-drying inks. This technique is well-suited for printing on various substrates, including plastics, films, and foils. Flexographic printing excels in high-speed production, making it ideal for large print runs. Recent advancements in flexography include the use of water-based inks and improved plate materials, enhancing print quality, and reducing environmental impact. - Screen Printing:

Screen printing, also known as silk screening, involves pressing ink through a mesh screen onto the printing surface. This method is renowned for its versatility and ability to print on a wide range of materials, including textiles, glass, ceramics, and metal. Screen printing finds applications in apparel, signage, promotional items, and artistic prints. Advancements in screen printing include the development of automated machinery, enabling faster production speeds and higher precision.

Conclusion:

As we conclude our exploration of the four types of printing, it becomes evident that each technique possesses unique characteristics and applications. Offset printing excels in high-volume projects, while digital printing offers customization and on-demand capabilities. Flexographic printing is ideal for packaging materials, and screen printing showcases its versatility across various substrates. By understanding these printing methods and staying updated with technological advancements, professionals can make informed decisions to optimize their printing processes and achieve exceptional results in their respective industries. So, embrace the power of printing and unlock endless possibilities!