In today's fast-paced business world, efficient labeling plays a crucial role in streamlining operations and enhancing productivity. Laser label printing has emerged as a popular choice due to its precision, versatility, and professional finish. In this comprehensive guide, we will delve into the intricacies of laser label printing, exploring the equipment, techniques, and best practices to help you achieve outstanding results.

Section 1: Understanding Laser Label Printing

1.1 What are Laser Labels?

1.2 Advantages of Laser Label Printing

1.3 Applications of Laser Labels

Section 2: Choosing the Right Equipment

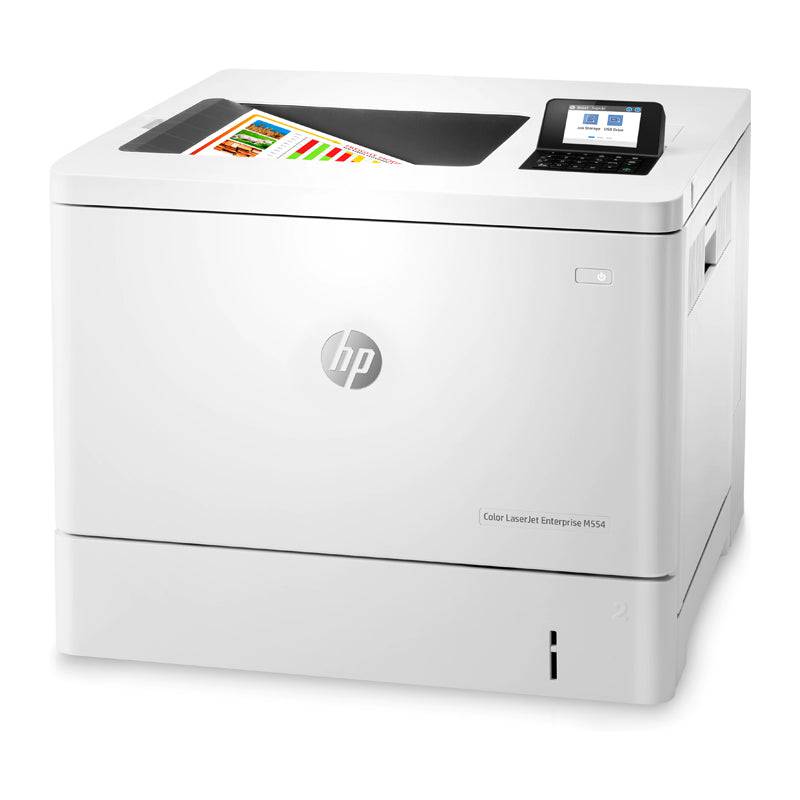

2.1 Laser Printers for Label Printing

2.2 Types of Laser Labels

2.3 Selecting the Right Label Material

2.4 Considerations for Label Design

Section 3: Designing Laser Labels

3.1 Label Design Software

3.2 Incorporating Branding Elements

3.3 Optimizing Label Layout

3.4 Ensuring Readability and Legibility

Section 4: Printing Laser Labels

4.1 Preparing the Printer

4.2 Loading Label Sheets

4.3 Adjusting Print Settings

4.4 Troubleshooting Common Printing Issues

Section 5: Label Finishing and Application

5.1 Label Cutting and Trimming Techniques

5.2 Label Adhesive Options

5.3 Proper Label Application Techniques

5.4 Label Storage and Handling Tips

Section 6: Maintenance and Troubleshooting

6.1 Printer Maintenance

6.2 Troubleshooting Print Quality Issues

6.3 Addressing Paper Jams and Feeding Problems

Conclusion:

Mastering the art of laser label printing empowers businesses to create professional-quality labels that enhance brand image and streamline operations. By understanding the equipment, design principles, and printing techniques, you can achieve outstanding results while maximizing efficiency. With this comprehensive guide, you are now equipped with the knowledge and skills to excel in laser label printing.