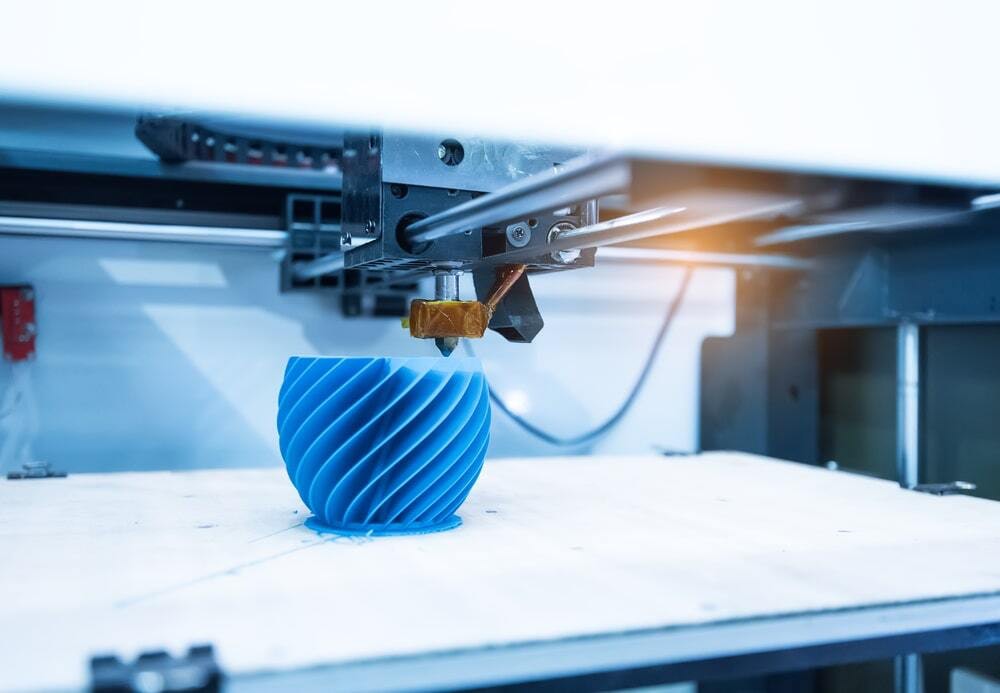

In recent years, 3D printing has revolutionized the way we create objects, enabling individuals to bring their ideas to life right from the comfort of their own homes. With the advancement of technology, the range of materials that can be 3D printed at home has expanded significantly. In this article, we will delve into the world of home 3D printing and explore the diverse materials that can be used to unleash your creativity.

- PLA (Polylactic Acid):

PLA is one of the most popular materials for home 3D printing. Derived from renewable resources such as cornstarch or sugarcane, PLA is biodegradable and environmentally friendly. It offers ease of use, low warping, and a wide range of vibrant colors. PLA is suitable for a variety of applications, including prototyping, artistic creations, and functional objects that don't require high heat resistance. - ABS (Acrylonitrile Butadiene Styrene):

ABS is another commonly used material in home 3D printing. It is known for its durability, impact resistance, and ability to withstand higher temperatures compared to PLA. ABS is ideal for functional parts, mechanical components, and objects that may be subjected to stress or higher temperatures. However, it emits fumes during printing, so proper ventilation is crucial. - PETG (Polyethylene Terephthalate Glycol):

PETG combines the best features of PLA and ABS. It offers excellent strength, flexibility, and impact resistance, making it suitable for a wide range of applications. PETG is also known for its transparency, making it a popular choice for creating clear or translucent objects. It is resistant to moisture and chemicals, making it suitable for functional parts and containers. - TPU (Thermoplastic Polyurethane):

TPU is a flexible filament that opens up possibilities for creating objects with rubber-like properties. It is highly elastic, resistant to abrasion, and can withstand repeated bending and stretching. TPU is commonly used for producing phone cases, shoe soles, gaskets, and other objects that require flexibility and impact resistance. - Wood and Metal Composites:

In recent years, advancements in 3D printing technology have allowed for the creation of filaments infused with wood or metal particles. These filaments enable the printing of objects with the appearance and properties of wood or metal. Wood-infused filaments can be sanded, stained, and even exhibit a wood-like smell. Metal-infused filaments can create objects with metallic finishes, suitable for decorative purposes or small functional parts. - Conductive Filaments:

For those interested in electronics and circuitry, conductive filaments offer exciting possibilities. These filaments contain conductive materials such as carbon or graphene, allowing for the creation of 3D printed objects with electrical conductivity. This opens up avenues for prototyping electronic components, sensors, and even wearable technology.

Conclusion:

Home 3D printing has evolved beyond its initial limitations, and a wide range of materials can now be used to bring ideas to life. From PLA and ABS to PETG, TPU, wood and metal composites, and conductive filaments, the possibilities are vast. Each material offers unique properties and applications, allowing individuals to explore their creativity and turn their visions into reality. With the right combination of materials and a dash of imagination, the world of home 3D printing is at your fingertips.