In the realm of automotive engineering, fuel pumps play a crucial role in delivering the lifeblood of vehicles - fuel. Understanding how mechanical fuel pumps work is essential for any automobile enthusiast or aspiring mechanic. In this comprehensive guide, we will delve into the intricate mechanics behind fuel pumps, exploring their components, functioning, and significance in the automotive industry.

- The Basics of Mechanical Fuel Pumps:

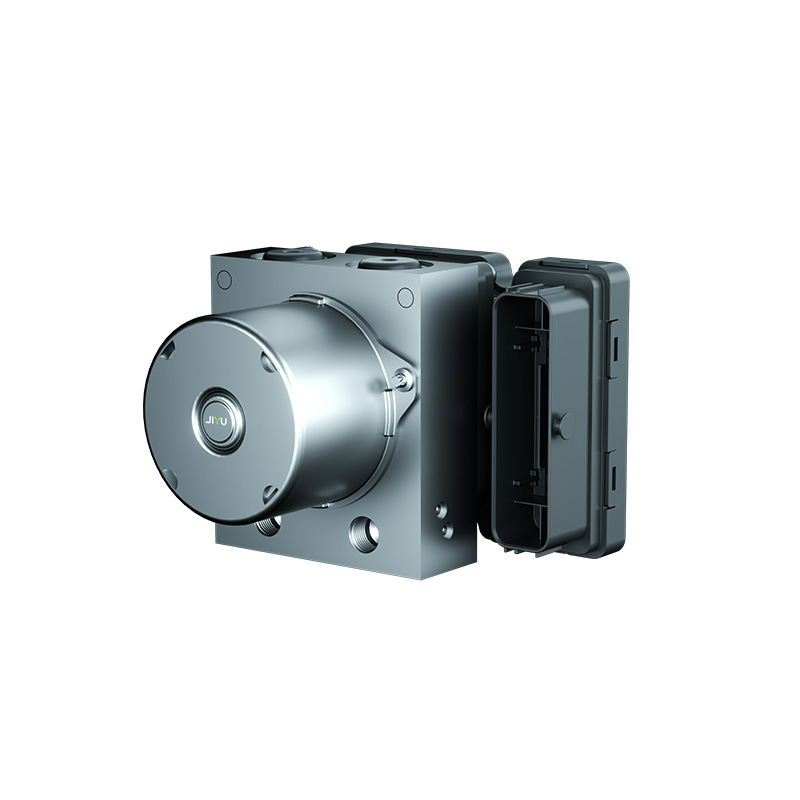

Mechanical fuel pumps are primarily found in older vehicles or those with carbureted engines. Unlike their electric counterparts, mechanical fuel pumps rely on the engine's motion to operate. They are typically mounted on the engine block and are driven by a camshaft or crankshaft. - Components of a Mechanical Fuel Pump:

A mechanical fuel pump consists of several key components, each playing a vital role in the fuel delivery process. These components include:

a. Diaphragm: The heart of the fuel pump, the diaphragm moves up and down, creating suction and pressure to draw fuel from the tank and deliver it to the engine.

b. Inlet and Outlet Valves: These valves regulate the flow of fuel, allowing it to enter the pump from the tank and exit towards the engine.

c. Lever Arm and Pushrod: The lever arm, connected to the diaphragm, converts the rotational motion of the camshaft or crankshaft into linear motion. The pushrod transmits this motion to the diaphragm, causing it to move. - The Fuel Delivery Process:

Understanding the fuel delivery process is crucial to grasp how mechanical fuel pumps operate. The process can be divided into four stages:

a. Intake Stroke: As the engine's camshaft or crankshaft rotates, the lever arm and pushrod move the diaphragm downwards, creating a vacuum. This vacuum opens the inlet valve, allowing fuel to enter the pump.

b. Compression Stroke: The diaphragm moves upward, compressing the fuel and closing the inlet valve.

c. Power Stroke: The upward movement of the diaphragm increases the pressure, opening the outlet valve and forcing the fuel towards the engine.

d. Exhaust Stroke: As the diaphragm reaches its maximum height, the outlet valve closes, preventing fuel from flowing back into the pump. - Advantages and Limitations of Mechanical Fuel Pumps:

Mechanical fuel pumps offer several advantages, including simplicity, reliability, and compatibility with carbureted engines. However, they also have limitations, such as lower fuel pressure compared to electric fuel pumps and the potential for fuel vapor lock in high-temperature conditions.

Conclusion:

Mechanical fuel pumps are a vital component in older vehicles, ensuring the efficient delivery of fuel to the engine. Understanding their functioning and components is essential for any automotive enthusiast or mechanic. By comprehending the intricacies of mechanical fuel pumps, one can troubleshoot issues, perform maintenance, and appreciate the engineering marvel behind these mechanical wonders.