In the realm of automotive engineering, fuel delivery systems play a pivotal role in ensuring optimal engine performance. Two key components within these systems are the high pressure fuel pump and the fuel pump. While their names may sound similar, they serve distinct functions and possess unique characteristics. In this article, we will delve into the intricacies of these two components, exploring their differences, functionalities, and the impact they have on overall engine efficiency.

- Understanding the Fuel Pump:

The fuel pump serves as the heart of the fuel delivery system, responsible for supplying fuel from the tank to the engine. Its primary function is to maintain a consistent flow of fuel at a specific pressure, ensuring a steady supply for combustion. Fuel pumps are typically located inside the fuel tank and are driven by an electric motor. They operate at relatively low pressures, typically ranging from 30 to 85 psi (pounds per square inch). - Unveiling the High Pressure Fuel Pump:

In contrast to the fuel pump, the high pressure fuel pump (HPFP) is specifically designed to handle the demands of direct injection systems. Direct injection engines require significantly higher fuel pressures to achieve efficient combustion. The HPFP operates at much higher pressures, often exceeding 2,000 psi. It is responsible for pressurizing the fuel to the required level before it is injected directly into the combustion chamber. - Key Differences:

3.1 Fuel Pressure:

The most significant difference between the two pumps lies in the fuel pressure they generate. While the fuel pump operates at relatively low pressures, the HPFP is engineered to deliver fuel at significantly higher pressures, meeting the demands of direct injection systems.

3.2 Location:

Another notable distinction is the physical location of the pumps. Fuel pumps are typically submerged in the fuel tank, while HPFPs are often located externally, near the engine. This positioning allows for more precise control over fuel pressure and delivery.

3.3 Design and Construction:

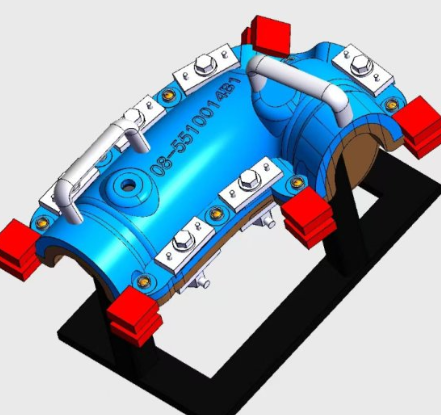

Due to the higher pressures involved, HPFPs are built with more robust materials and intricate designs. They incorporate advanced technologies such as piston-driven mechanisms or cam-driven systems to generate the required pressure. Fuel pumps, on the other hand, are relatively simpler in design, focusing on maintaining a consistent flow of fuel.

- Impact on Engine Performance:

The differences between the two pumps directly influence engine performance. The high pressure fuel pump enables direct injection systems to achieve better fuel atomization, resulting in improved combustion efficiency, reduced emissions, and enhanced power output. Fuel pumps, while crucial for maintaining a steady fuel supply, do not directly impact combustion efficiency.

Conclusion:

In summary, the high pressure fuel pump and the fuel pump are distinct components within the fuel delivery system, each serving a specific purpose. The fuel pump ensures a consistent flow of fuel from the tank to the engine, while the high pressure fuel pump pressurizes fuel to meet the demands of direct injection systems. Understanding these differences is essential for automotive enthusiasts and professionals alike, as it sheds light on the intricacies of engine performance and fuel delivery systems. By optimizing these components, engineers can unlock the full potential of modern combustion engines.