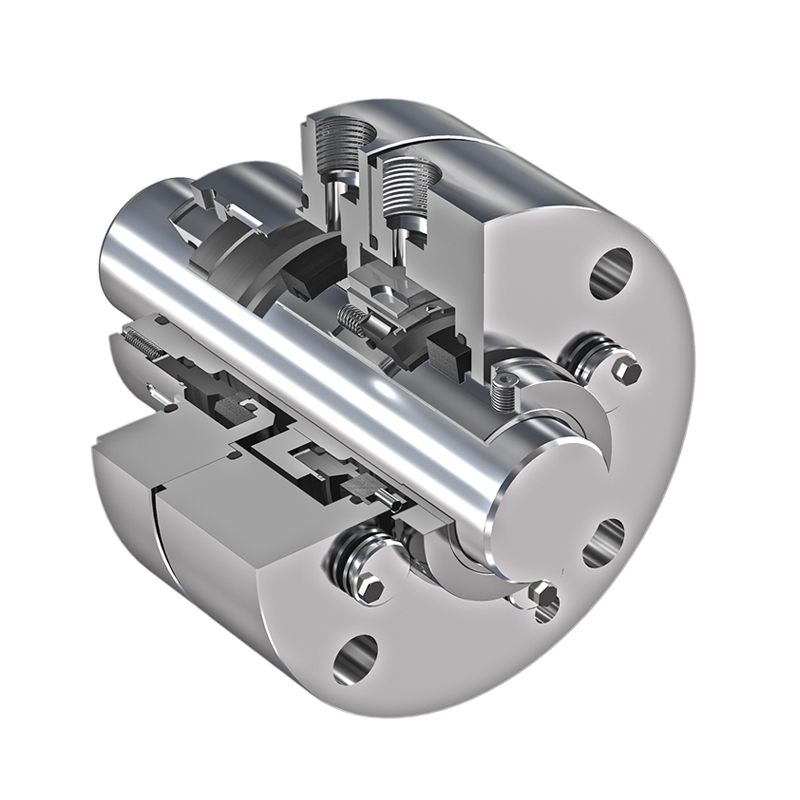

Mechanical seals are critical components in many industrial applications, including pumps, compressors, and mixers. They play a crucial role in preventing leaks and maintaining the integrity of the system. However, mechanical seal failure is a common problem that can lead to costly downtime, repairs, and even safety hazards. In this article, we will explore the most common cause of mechanical seal failure and provide practical tips on how to prevent it.

The most common cause of mechanical seal failure is improper installation and maintenance. Mechanical seals are precision components that require careful handling and installation. Even minor errors during installation, such as misalignment, insufficient lubrication, or improper torque, can cause premature failure. Similarly, inadequate maintenance, such as failure to replace worn components or clean the seal faces, can also lead to failure.

Another common cause of mechanical seal failure is abrasive or corrosive media. Mechanical seals are designed to operate in specific environments, and exposure to harsh chemicals, abrasive particles, or high temperatures can cause damage to the seal faces, springs, and other components. In addition, improper material selection can also lead to premature failure. For example, using a seal made of incompatible materials can result in chemical attack, swelling, or cracking.

Vibration and misalignment are also significant contributors to mechanical seal failure. Vibrations can cause excessive wear and tear on the seal faces, leading to leakage and failure. Misalignment, on the other hand, can cause uneven loading on the seal faces, resulting in premature wear and failure. Both of these issues can be caused by improper installation, worn bearings, or other mechanical problems.

To prevent mechanical seal failure, it is essential to follow proper installation and maintenance procedures. This includes ensuring proper alignment, lubrication, and torque, as well as regular inspection and replacement of worn components. It is also important to select the right seal material for the application and to avoid exposure to abrasive or corrosive media whenever possible. Finally, addressing any mechanical issues that may contribute to vibration or misalignment can also help prevent seal failure.

In conclusion, mechanical seal failure is a common problem that can have significant consequences for industrial operations. By understanding the root causes of failure and taking preventive measures, such as proper installation and maintenance, material selection, and addressing mechanical issues, it is possible to minimize the risk of failure and ensure reliable operation.