In the intricate landscape of mechanical engineering, bolted joints stand as fundamental elements, playing a pivotal role in assembling structures, machinery, and myriad components. This article embarks on an insightful journey into the world of bolted joints, unraveling their essence, applications, and the key considerations that engineers must navigate to ensure precision and reliability in their designs.

1. Introduction to Bolted Joints

A. Defining Bolted Joints

Initiate the article by defining bolted joints as connections achieved by the use of bolts, nuts, and washers. Discuss their ubiquity in diverse industries, emphasizing their crucial role in creating secure and disassemblable connections.

B. Importance in Engineering Design

Highlight the importance of bolted joints in engineering design, where they offer a balance between strength, flexibility, and ease of assembly. Discuss their versatility in applications ranging from aerospace to construction.

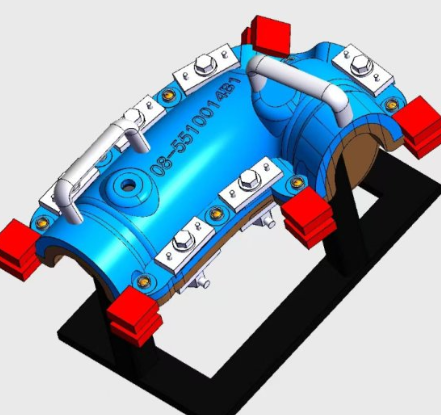

2. Components of a Bolted Joint

A. Bolts and Nuts

Examine the components that constitute a bolted joint, focusing on the bolts and nuts. Discuss the varying materials, sizes, and threading options available, each tailored to specific applications and load requirements.

B. Washers and Their Functions

Dive into the role of washers in bolted joints. Discuss how washers distribute load, prevent damage to surfaces, and enhance the overall performance and longevity of the connection.

3. Types of Bolted Joints

A. Permanent and Temporary Joints

Explore the distinction between permanent and temporary bolted joints. Discuss scenarios where permanent connections are preferred for enduring stability, while temporary joints provide flexibility for disassembly and modifications.

B. Preloaded and Non-Preloaded Joints

Examine the concept of preloading in bolted joints, where bolts are tightened to create initial tension. Discuss how preloaded joints offer enhanced reliability and resistance to loosening under dynamic loads.

4. Factors Influencing Bolted Joint Performance

A. Torque and Tension

Delve into the relationship between torque and tension in bolted joints. Discuss how precise torque application is critical to achieving the desired tension, ensuring optimal clamping force.

B. Material Selection

Highlight the importance of material selection in bolted joint performance. Discuss how choosing the right materials for bolts and nuts involves considerations of strength, corrosion resistance, and environmental factors.

5. Applications Across Industries

A. Aerospace Engineering

Explore the significance of bolted joints in aerospace engineering. Discuss their role in assembling aircraft components, where lightweight materials and precise connections are paramount.

B. Construction and Infrastructure

Examine the use of bolted joints in construction and infrastructure projects. Discuss their application in connecting structural elements, facilitating ease of assembly, disassembly, and maintenance.

6. Challenges and Solutions in Bolted Joints

A. Loosening and Vibrations

Address common challenges in bolted joints, such as the risk of loosening under dynamic loads or vibrations. Discuss solutions, including the use of locking mechanisms or thread-locking compounds.

B. Corrosion Resistance Strategies

Explore strategies to address corrosion in bolted joints. Discuss the use of corrosion-resistant coatings, materials, and maintenance practices to ensure long-term reliability.

Conclusion: Bolting the Future of Engineering

Summarize the article by emphasizing the indispensable role of bolted joints in shaping the future of engineering. Highlight how a nuanced understanding of their components, types, and influencing factors empowers engineers to create robust and reliable connections in diverse applications.