Relays, the unsung heroes of electrical systems, play a crucial role in controlling and protecting circuits. These electromechanical devices are widely used in various industries, from automotive and telecommunications to industrial automation and power distribution. Understanding how relays are classified is essential for engineers and technicians working with electrical systems. In this article, we will delve into the intricate world of relay classification, exploring the different types, their applications, and the factors that influence their selection.

- Electromagnetic Relays:

Electromagnetic relays are the most common type and are classified based on their operating principles. This classification includes:

a. Reed Relays: Utilizing reed switches, these relays offer high switching speeds and are often used in telecommunications and automatic test equipment.

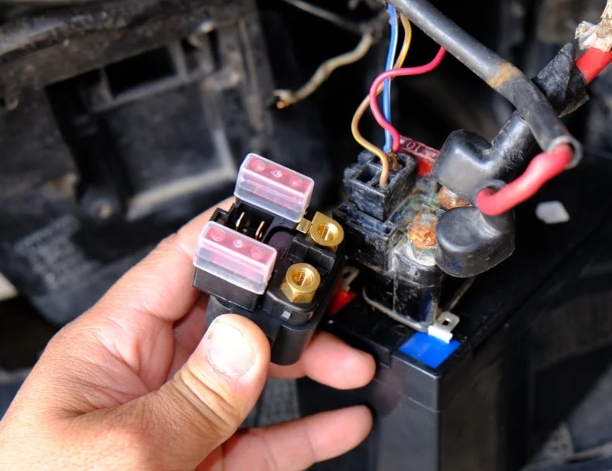

b. Armature Relays: These relays employ an armature mechanism to control the circuit, making them suitable for applications requiring high switching currents.

c. Polarized Relays: With a permanent magnet, these relays provide stable operation and are commonly used in automotive applications. - Solid-State Relays:

Solid-state relays (SSRs) have gained popularity due to their compact size, fast switching speeds, and high reliability. They are classified based on their output device and include:

a. Thyristor-Based SSRs: These relays use thyristors (SCRs) as the output device, offering high current-carrying capabilities and excellent noise immunity.

b. Triac-Based SSRs: Employing triacs as the output device, these relays are ideal for AC power control applications, such as lighting and motor speed control.

c. MOSFET-Based SSRs: With MOSFETs as the output device, these relays provide low on-resistance and high switching speeds, making them suitable for various industrial applications. - Hybrid Relays:

Hybrid relays combine the advantages of both electromagnetic and solid-state relays. They are classified based on their construction and include:

a. PhotoMOS Relays: These relays utilize optically coupled MOSFETs, offering high isolation voltage and low leakage current, making them suitable for medical and measurement equipment.

b. Hybrid Reed Relays: Combining reed switches with solid-state components, these relays provide the benefits of both technologies, making them suitable for demanding applications in aerospace and defense. - Protective Relays:

Protective relays are designed to monitor electrical systems and protect them from faults and abnormalities. They are classified based on their function and include:

a. Overcurrent Relays: These relays detect excessive current flow and protect circuits from overloads and short circuits.

b. Differential Relays: Employed in transformers and motors, these relays compare currents entering and leaving the equipment to detect internal faults.

c. Distance Relays: Used in transmission lines, these relays measure the impedance between the relay location and the fault to determine the fault's distance.

Conclusion:

Relays are classified based on various factors, including their operating principles, output devices, construction, and functions. Understanding these classifications is crucial for selecting the right relay for specific applications. From electromagnetic and solid-state relays to hybrid and protective relays, each type offers unique advantages and is tailored to meet specific industry requirements. By comprehending the intricacies of relay classification, engineers and technicians can make informed decisions, ensuring optimal performance and reliability in electrical systems.